For system integrators designing surveillance, security, and industrial monitoring control rooms, ensuring operators have reliable visibility across multiple feeds —including CCTV feeds, NVR outputs, dashboards, and broadcast signals — is a top priority. Traditionally, this meant using numerous monitors or relying on external multiviewer boxes and switchers. While functional, these solutions add complexity, require more hardware, and create more points of failure.

A quad-view Picture-by-Picture PBP monitor (sometimes referred to as a multi-input display or multiviewer monitor) changes that equation. By combining four inputs or more into a single screen with flexible layouts, these displays simplify hardware setups, reduce failure points, and keep critical information in view at all times. For integrators, this means easier installations, lower service costs, and long-term reliability for clients.

👉If you’re new to PBP monitors and want to understand why traditional workflows are being replaced, start here: Rethinking Visual Workflows: The Rise of Multi-Input Displays

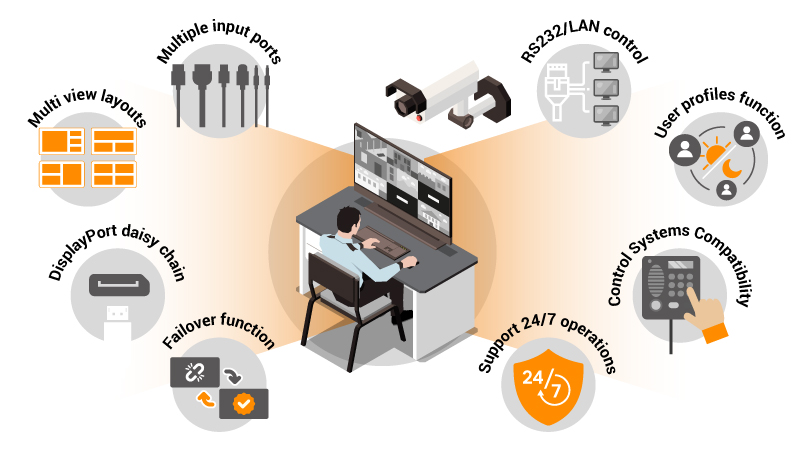

To help you make an informed decision, this guide outlines the eight essential features that separate true professional-grade multi-input displays from standard multi-window alternatives.

When specifying displays for mission-critical environments, not all quad-view monitors are equal. Below are the eight must-have features every system integrator should demand.

A professional PBP monitor should natively support at least four independent video inputs, typically a mix of HDMI, DisplayPort, or SDI, and display all of them simultaneously without needing external switchers or software. This capability is more than convenience: it eliminates reliance on third-party devices, reduces the number of devices to configure, and removes potential points of failure.

For system integrators, fewer components mean faster deployment, lower costs, and fewer service calls in the long run.

What to look for:

Quad-view doesn’t only mean 2×2 grids. Professional monitors enable operators to select from various window arrangements, such as a primary source with smaller supporting windows, side-by-side comparisons, or balanced grids. This flexibility ensures that different operators can tailor the display to their priorities without disrupting workflow.

In practice, an operator may begin by viewing four dashboards equally to maintain a broad overview. If something unusual appears, they can adjust the layout to enlarge a specific feed and examine the issue more closely. This adaptability keeps situational awareness aligned with immediate needs.

Why it matters:

Scaling up a control room often means adding more displays. DisplayPort, DP daisy-chain (MST), provides a streamlined way to expand without racks of processors or excessive cabling. By connecting monitors in sequence, operators gain larger visual workspaces with fewer devices in between. This simplifies expansion, keeps installations tidy, and makes systems easier to maintain.

For integrators, MST reduces installation complexity while offering clients a future-proof solution that adapts as monitoring needs grow.

Why it matters:

In mission-critical environments, reliability is everything. Look for displays that support automatic input failover. Failover is more than a technical safeguard — it’s a risk management tool. When a primary feed fails, a professional monitor with input prioritisation automatically switches to a predefined backup and sends feedback to the primary monitor. This eliminates the downtime and distraction associated with manual intervention.

In critical sectors such as public safety or industrial monitoring, even a few seconds without visibility can escalate into costly mistakes or compromised safety. Monitor-level failover ensures that visibility is maintained when it matters most.

Benefits:

Managing one display locally is straightforward, but managing dozens or hundreds across sites is another challenge altogether. That’s where RS232 and IP-based control become critical.

Remote management allows integrators to centralise adjustments, diagnose issues, and roll out updates without dispatching technicians. This lowers support costs, reduces downtime, and supports service-level agreements more effectively. For clients, it means faster response times and fewer disruptions to daily operations.

Check for:

In control rooms, multiple operators often share the same workstation across different shifts. Without profile memory, each operator would need to manually reconfigure layouts and settings. Professional PBP monitors allow profiles and OSD presets to be saved and recalled instantly. This consistency reduces training requirements, speeds up shift transitions, and minimises setup errors during urgent scenarios.

For integrators, it demonstrates value by providing systems that adapt to users, rather than forcing users to adapt to the systems.

Key advantages:

When time is critical, navigating through on-screen menus slows operators down. That’s why compatibility with physical keypads or integration into wider control systems is so valuable. System-integrated keypads allow immediate switching between sources or layouts with a single button press. This tactile speed is critical in surveillance or emergency settings, where quick action can prevent escalation.

For integrators, keypad support means systems that fit seamlessly into existing workflows without requiring retraining.

Why it matters:

Consumer-grade monitors may work for offices, but they aren’t designed for continuous operation. Professional PBP monitors must be designed for continuous 24/7 use, featuring thermal safeguards, heat monitoring, and durable materials. The benefit extends beyond durability: reliable hardware directly impacts the total cost of ownership. Replacing failed consumer monitors is disruptive and expensive, but professional-grade units maintain uptime and deliver long-term savings for both integrators and end-users.

Why it matters:

Before recommending a quad-view PBP monitor, confirm that it includes:

✅ Minimum of 4 independent input ports (HDMI, DP, or SDI)

✅ Flexible, customisable viewing layouts

✅ DP daisy chain (MST) support for expansion

✅ Built-in failover for uninterrupted monitoring

✅ RS232 and LAN remote management

✅ User profiles and OSD presets

✅ Keypad/control system ports and compatibility

✅ Certified for 24/7 operation

PBP monitors with quad-view support aren’t just about displaying four sources at once. They are professional-grade tools designed to scale with demand, protect uptime, and fit seamlessly into mission-critical workflows. For system integrators, specifying monitors with these eight features ensures:

Bottom line: the right monitor shifts cost from field labour to up‑front specification—where integrators control risk.

👉 See how control rooms are rethinking their visual workflows multi-input PBP displays or,